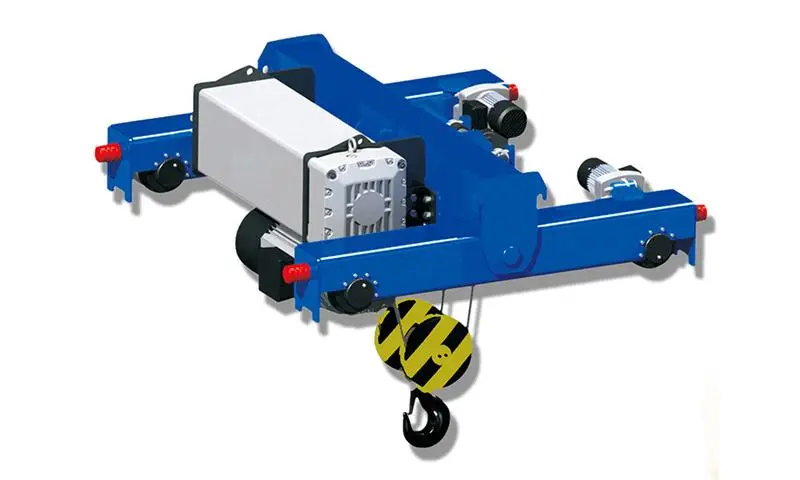

Wire Rope Electric Hoist with Trolley

The wire rope electric hoist with trolley is an efficient and convenient lifting equipment widely used in various industrial, construction and logistics fields. It is driven by an electric motor and uses wire ropes and pulleys to lift and move heavy objects. It has the characteristics of compact structure, easy operation, safety and reliability.

How it works

The wire rope electric hoist with trolley is mainly composed of motor, reducer, drum, wire rope, pulley block, trolley and control system. When the motor starts, the high-speed rotating motor output is converted into low-speed, high-torque power through the reducer, driving the drum to rotate. The wire rope wound on the drum realizes lifting and lowering movement under the rotation of the drum. At the same time, through the guidance of the pulley block, the wire rope can drive the trolley to move on the track, thereby realizing the lifting and horizontal movement of heavy objects.

Design Features

● It adopts an integrated design, has a compact structure, takes up little space, and is easy to install and use.

● The equipment adopts electric control and is easy to operate. You can lift and move heavy objects through the control button or remote control.

● It has multiple safety protection measures, such as overload protection, limit protection, etc., to ensure the safety and reliability of the equipment during operation.

● The use of advanced motor and reducer design makes the equipment highly efficient and energy-saving during operation, reducing usage costs.

● Suitable for various environments and usage scenarios, and can be customized according to different needs.

Regular maintenance

● Regularly inspect the equipment, including motors, reducers, drums, wire ropes, pulleys, trolleys and control systems. Check whether all components are intact and whether they are loose or worn.

● Clean and maintain the equipment regularly and remove dust and debris from the surface of the equipment. For easy-to-wear parts such as wire ropes and pulley blocks, appropriate amounts of lubricating oil should be applied for maintenance.

● Check whether the fasteners of each component of the equipment are loose. If they are loose, tighten them in time. In particular, the connection parts between the wire rope and the drum, pulley block and other parts should be ensured to be fastened reliably.

● Inspect and maintain the equipment's control system to ensure that control buttons, switches and other components are working properly. If there is any damage or failure, it should be replaced or repaired in time.