Installation Instructions for Column Cantilever Jib Crane

As a common light lifting equipment, column cantilever jib crane is widely used in workshops, warehouses, production lines and other places, and can efficiently complete material handling and assembly tasks. In order to ensure the stable operation of the equipment and the safety of the operation, correct installation is essential. We will introduce the installation steps and precautions of the column cantilever jib crane in detail to help you successfully complete the equipment installation and ensure its optimal performance.

Preparation before installation

1. Confirm the equipment and accessories

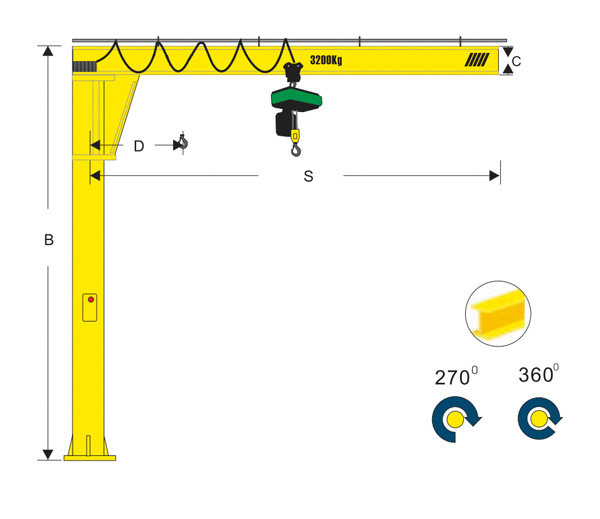

● Please confirm that the equipment is well packaged, all accessories are complete, and consistent with the ordered equipment model. Generally, the main components of the column cantilever jib crane include columns, cantilever booms, electric or manual drive systems, hooks or other hoists, limit switches, etc.

2. Check the installation site

● Make sure that the installation site is flat and solid and can withstand the weight of the crane and the load. Uneven or unstable ground may cause the equipment to tilt or be damaged.

● There should be enough space on site to ensure that the cantilever boom of the cantilever jib crane can cover the working area and have enough lifting space.

3. Tool preparation

● Prepare necessary installation tools such as screwdrivers, wrenches, levels, measuring tools, power tools, etc. to ensure a smooth installation process.

4. Safety protection

● Please wear appropriate protective equipment during installation, such as hard hats, gloves, etc., to ensure the safety of operators.

Installation steps of column cantilever jib crane

1. Installation of column

● Positioning: Place the column in the predetermined position according to the on-site measurement results. Make sure that the vertical direction of the column is parallel to the ground and use a level to confirm.

● Fix the column: Fix the base of the column to the ground with bolts. If there are accessories for anchor bolts, make sure the bolts are tightened and check whether the column is stable.

● Inspection: After the installation is completed, confirm again whether the column is firm and vertical to avoid problems in subsequent installation.

2. Installation of cantilever arm

● Positioning arm: Align the connection between the cantilever arm and the column to ensure the installation position is accurate.

● Fixed connection: Fix the arm firmly to the column with bolts or other connectors. Make sure the screws are tightened when connecting to avoid looseness.

● Adjust the cantilever length: If the cantilever jib crane has an adjustable length design, the length of the cantilever arm needs to be adjusted according to actual work needs during installation.

3. Install the drive system

● Install the electric drive: If it is an electric-driven column cantilever jib crane, install the drive components such as the motor and reducer to the specified position, and ensure that the motor cable is connected correctly.

● Connect the power supply: Connect the power supply of the electric drive system to the grid, ensure that the power supply voltage meets the equipment requirements, and be sure to turn off the power supply when connecting the power supply to avoid electric shock.

● Check the drive system: After the installation is completed, check the operation of the electric drive system manually or through the control system to ensure that there is no abnormal noise or vibration.

4. Install the hook and safety device

● Hook: Install the hook or other lifting equipment as needed to ensure that the lifting equipment is firmly connected to the wire rope or fiber belt.

● Safety device: Install safety equipment such as overload protection device and limit switch to ensure that the equipment will not be overloaded or exceed the stroke during operation, and ensure safe operation.

5. Debugging and testing

● After completing all installation steps, debug and test the equipment. Start the crane step by step, test the lifting, moving and other functions, and ensure that the equipment runs smoothly and without abnormalities.

● Carry out load test, check the lifting capacity of the equipment, and confirm that all safety devices are working properly.

Inspection and precautions after installation

1. Check the tightness of the bolts

● After installation, check whether all bolts and connectors are tightened to avoid loosening during the operation of the equipment.

2. Check the electrical system

● Ensure that the electrical system is connected normally and the power supply is safe, and check whether the limit switch and overload protection device can work properly.

3. Cleaning and lubrication

● Clean the surface of the equipment and remove debris and dust generated during the installation process. Properly lubricate the parts that need lubrication to ensure smooth operation of the equipment.

4. Safety inspection

● Before officially putting it into use, conduct a comprehensive safety inspection to confirm that the equipment meets the safety operation standards. In particular, check whether the load-bearing capacity and safety devices of the lifting equipment meet the requirements to ensure safety during use.

Through the correct operation of the above steps, you will be able to successfully complete the installation of the column jib crane and bring a more efficient and safe material handling experience to your work. If you have any questions about installation or use, please feel free to contact KFCS CRANE. We will provide you with professional technical support and services to ensure the efficient operation of your equipment!