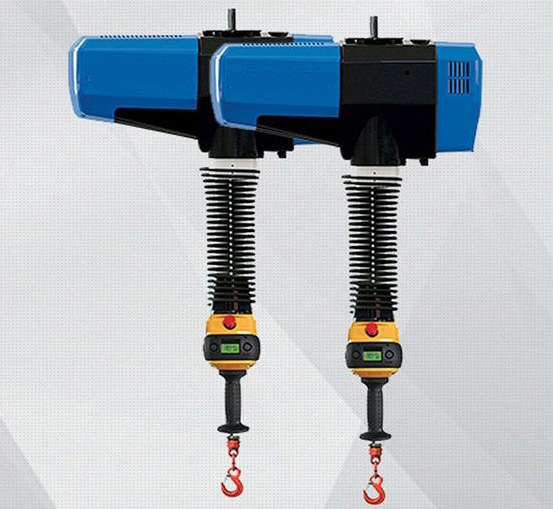

New intelligent balancer

The balancer is usually used for material handling. It mainly uses the energy stored in the coil to make the suspended operating tools weightless, thus reducing the labor intensity of manual operation. It is mainly used for automobile die, part welding, assembly line and various fixed positions with concentrated workload, heavy operating tools and long service life. However, when the spring balancer is used as a lifting aid to transport heavy work pieces, due to the serious swing of starting and braking, it is not easy for the work pieces to reach the specified or expected process position. Even when the operator grabs the suspender or the workpiece with workpiece, he cannot lift the heavy object at a steady speed, which cannot further reduce the labor intensity of the operator.

The utility model relates to a novel intelligent balancer, which is characterized by comprising a balancer, a motor, a weighing module and an intelligent processing module. The motor output shaft is connected with the winding wheel of the balancer to control the positive and negative rotation of the winding wheel. The upper part is connected with the rope, and the fixed side of the weighing module is connected with the lower part. The carrying side of the rope is connected with the upper part of the suspender for lifting the workpiece, the output end of the weighing module is connected with the input end of the intelligent processing module, the intelligent processing module is connected with the motor driver wirelessly or wirelessly, and the motor driver is connected with the motor to control the motor action.

The utility model relates to a novel intelligent balancer, which is characterized by comprising a balancer, a motor, a weighing module and an intelligent processing module. The motor output shaft is connected with the winding wheel of the balancer to control the positive and negative rotation of the winding wheel. The upper part is connected with the rope, and the fixed side of the weighing module is connected with the lower part. The carrying side of the rope is connected with the upper part of the suspender for lifting the workpiece, the output end of the weighing module is connected with the input end of the intelligent processing module, the intelligent processing module is connected with the motor driver wirelessly or wirelessly, and the motor driver is connected with the motor to control the motor action.

The utility model relates to a novel intelligent balancer, which is characterized by comprising a balancer, a motor, a weighing module and an intelligent processing module. The motor output shaft is connected with the winding wheel of the balancer to control the positive and negative rotation of the winding wheel. The upper part is connected with the rope, and the fixed side of the weighing module is connected with the lower part. The carrying side of the rope is connected with the upper part of the suspender for lifting the workpiece, the output end of the weighing module is connected with the input end of the intelligent processing module, the intelligent processing module is connected with the motor driver wirelessly or wirelessly, and the motor driver is connected with the motor to control the motor action.